Some FGS users with multiple, non-integrated

systems use FGS to collect data from each system. The FGS database

ties it all together and provides the planners with all of the information

they need in one place.

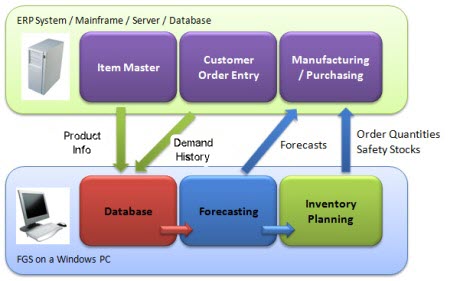

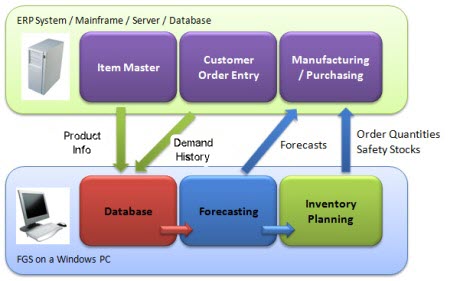

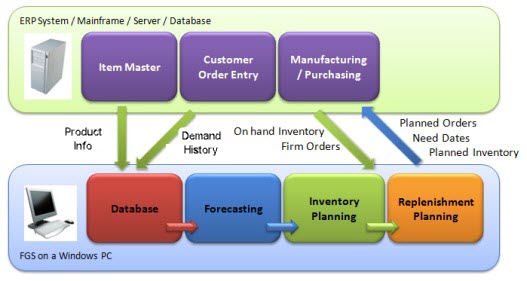

FGS Primary Modules (alone)

If

you already have an MRP or replenishment planning system, FGS

generates forecasts and inventory targets.

Data imported from your current system into FGS:

- Demand History: Demand for a part at a location. Data

may be "bucketed" to daily, weekly, monthly, etc. periods or data may

be at the transaction level. We recommend transactions so that

FGS can flexibly summarize the demand by selectable periods.

You can also do statistical analyses to identify outlier

transactions.

- Product Information: Part number, description, lead time, cost,

purchasing or manufacturing data, and any other data to describe or

classify your data.

Data

exported to your ERP system:

Data

exported to your ERP system:

-

Forecasts: These may be weekly, daily, monthly, etc., in any unit

of measure or format that your system requires.

-

Order quantities: FGS computes recommended replenishment

quantities (EOQ or adjusted order quantity).

- Safety stocks: These are calculated to provide the desired

service levels in the inventory module.

- Reorder points: If you don't have an MRP system you can upload

reorder points (which are a combination of forecast and safety stock).

- Other information such as ABC inventory classifications, and any

calculated values.

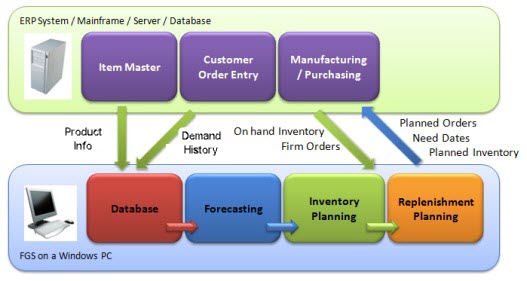

With Optional Replenishment Planning Module

If you do not have an MRP system and wish to reap the benefits of time-phased replenishment, the Replenishment Planning Module is for you.

Even if you run MRP this module can provide significant benefits,

especially at the finished goods level.

Replenishment Planning needs to know the replenishment status:

Replenishment Planning needs to know the replenishment status:

- On hand inventory quantities, allocations, quality holds, etc.

If you are replenishing at the warehouse level, this would include

that inventory as well.

- Firm replenishment orders such as manufacturing orders,

purchase orders, and work orders.

- Additional information about vendors, replenishment policies, etc.,

can be helpful.

Replenishment Planning generates planning information:

- Suggested planned orders to be firmed or shared with suppliers

for long term planning.

- Weekly net requirements for your replenishment system to plan

- Suggested need dates for existing firm planned orders

- Other information such as work center capacity requirements,

projected weekly inventory levels, cash flows, etc.

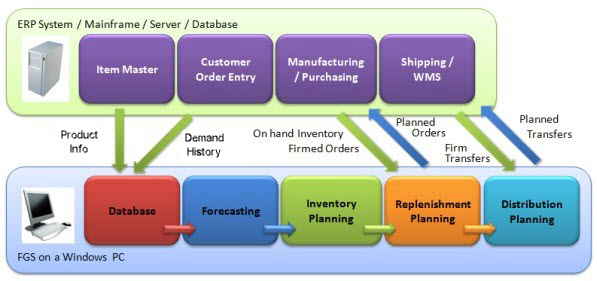

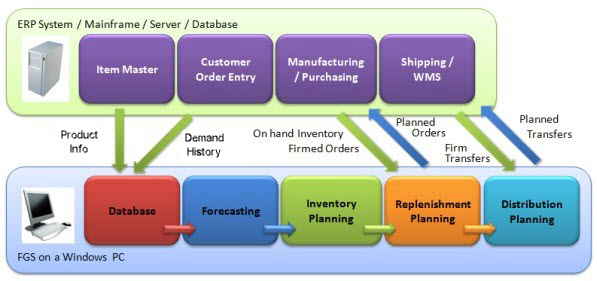

With Optional Distribution Planning Module

If you have complex distribution requirements FGS can plan your

warehouse transfers.

Distribution

needs some additional information from your Shipping or Warehouse

Management System

Distribution

needs some additional information from your Shipping or Warehouse

Management System

Distribution Planning generates information:

- Suggested short and long term transfers

- Allocation plans to balance inventory just before shipping

- Recommended changes to shipping plans

Data

exported to your ERP system:

Data

exported to your ERP system: Replenishment Planning needs to know the replenishment status:

Replenishment Planning needs to know the replenishment status: Distribution

needs some additional information from your Shipping or Warehouse

Management System

Distribution

needs some additional information from your Shipping or Warehouse

Management System